7 Costly Dummy Block Mistakes … and How to Avoid Them

Hydraulic Press Maintenance Best Practices

Maximize Press Throughput and Extend Tool Life with These Expert Tips

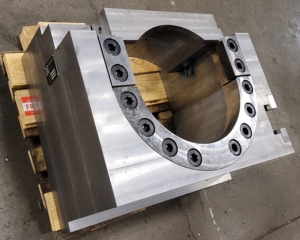

When it comes to hydraulic extrusion presses, your dummy block might be small, but it plays a massive role in maintaining performance and quality, and avoiding costly downtime. From sealing and alignment to lifespan and maintenance, the dummy block is a wear item you can’t afford to neglect.

When it comes to hydraulic extrusion presses, your dummy block might be small, but it plays a massive role in maintaining performance and quality, and avoiding costly downtime. From sealing and alignment to lifespan and maintenance, the dummy block is a wear item you can’t afford to neglect.

Here are 7 of the most common dummy block mistakes, and how to steer clear of them courtesy of your friends at Dunaway.

- Skipping the Preheat: A Shortcut That Costs You

Many operators assume the dummy block will heat up quickly during extrusion, but skipping preheat introduces thermal shock, reducing toughness and leading to microcracks in as little as seven days. Preheat to around 600°F (315°C) before use, either in an oven or by placing it in the center of the container for a few hours for a controlled warm-up.

- Ignoring Daily Visual Inspections

Aluminum buildup, wear on the land, or damaged springs (if applicable) can drastically impact extrusion quality and increase downtime. A daily visual inspection should check:

- For buildup on the face and land

- Spring action and mandrel movement – on blocks with springs

- Tightness of all cap screws and bayonet lugs

- Letting Your Block Grow … Without Noticing

As the dummy block expands with use, it can exceed the material’s creep limits. An increase of just 0.020” in diameter may signal permanent deformation. Once blisters and high drawback loads appear, it’s already too late. Record diameter regularly. It may help to rotate the block 90° daily to equalize wear in some setups.

- Running a Dirty, Under-Lubricated Dummy Block

Improper lubrication leads to aluminum sticking and shortens tool life. Automatic or manual swabbing of the dummy face before each extrusion cycle is preferred. For blocks that are rebuildable, a weekly internal lube with boron nitride dry powder is recommended. Running the block through caustic once a week can also increase usable life.

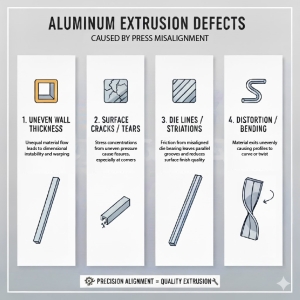

- Using a Poor Container Seal Face

A rough or dirty container seal face causes misalignment and even breakage. Key reminders:

- Never let the dummy block pass fully through the container.

- Keep aluminum from building up on the die/container interface.

- Never use acetylene torches to clean sealing faces. Use proper mechanical or chemical methods instead.

- Failing to Track Usage and Wear

Each dummy block should be serialized and tracked for:

- Install date

- Number of billets pushed

- Outside diameter at two 90° positions

This recordkeeping allows proactive replacement before defects or catastrophic failure occur.

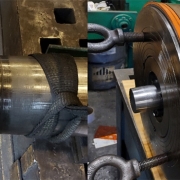

- Overlooking Attachment Issues

Whether your press uses threaded, tie-bar, or bayonet attachments, poor installation or looseness invites disaster. If the block loosens, the full extrusion force may break the attachment stud. Routine inspection and tightening – and avoiding thread damage during swap – is essential.

Trust Dunaway: Your Partner in Preventive Maintenance Excellence

Dummy block failures often cascade into larger, more expensive problems. At Dunaway, we know hydraulic extrusion presses down to every bolt and bushing. Whether you need help diagnosing extrusion issues, optimizing your tooling life or sourcing replacements, all roads lead to Dunaway.

Visit dunawayinc.com to learn more about how we keep your press – and your business – running stronger, longer.