7 Press Alignment Mistakes That Are Undermining Your Extrusion Quality

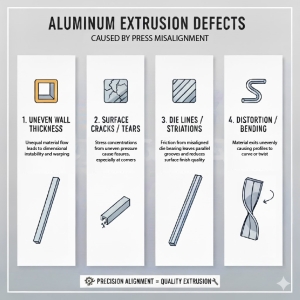

At Dunaway, we’ve seen how something as fundamental as alignment can make or break the performance of an extrusion press. When a press is even just slightly misaligned, it does more than shorten the lifespan of components. It erodes extrusion quality, introduces inconsistencies and ultimately chips away at productivity.

Most shops know alignment matters. But too often, we see well-intentioned teams making the same mistakes – either because the symptoms are subtle or because they’re relying on outdated assumptions.

Here are seven common alignment mistakes we see in the field, what they’re doing to your press and how to fix them before the damage gets worse.

- Assuming the Dummy Block Will “Self-Center”

Yes, the dummy block will compensate a little. But “a little” isn’t enough. Relying on it to correct a misaligned container or stem leads to uneven skull formation, which is one of the earliest signs your alignment is off. Over time, this causes metal inflow, surface defects on extrusions and unpredictable die wear.

Fix it: Use a cold cleanout block with expansion slots to inspect skull shape daily. Uniformity is your friend.

Definition: In aluminum extrusion, the “skull” is the thin layer of aluminum oxide and other impurities from the surface of the billet that is left fused to the inside of the container liner after the extrusion process.

- Correcting Die-to-Container Alignment by Raising the Container

This one’s more common than you’d think. Technicians will raise the container to meet the die, especially when chasing tolerance issues, without realizing it “cocks” the container off-axis. That’s how you end up with a tilted container, off-center flow and worn container liners.

Fix it: Always align the die to the container, not the other way around. And confirm alignment at operating temperature, not when cold.

- Ignoring Stem-to-Container Misalignment

When the stem doesn’t enter the container straight, you get skull buildup on one side, inflow, and eventually wear on the dummy block, container liner and even the stem itself. You may also notice unusual surface issues on extrusions.

Fix it: Daily alignment checks should include inspecting the uniformity and weight of the skull. If the shape is off or the weight is trending, it’s time to act.

- Trusting Dummy Tool Stacks for Precise Measurements

Visual checks using dummy stacks are a more convenient way of quickly checking alignment, they often give a false sense of security and do not provide a numerically measurable value. In addition, presses at rest, without extrusion pressure and temperature, don’t behave the same as when in production.

Fix it: Use a target die or leave a butt on the die at operating conditions to get a true picture of alignment. It’s more accurate and reveals real-world misalignment.

- Overlooking the Effects of Heat on Alignment

Presses shift with heat – literally. If you’re checking alignment with a cold press or while the container heaters are still on but the press hasn’t cycled, you’re not seeing the actual operational geometry.

Fix it: Perform alignment checks when the press is at normal operating temperature. This accounts for thermal expansion and provides the most accurate readings.

- Forgetting to Recheck Tie Rod Level and Pre-Stress

Over time, foundation settling or even routine operation can knock your tie rods out of level. And once that happens, every measurement built off those reference points is compromised.

Fix it: Check tie rod level and pre-stress regularly using a machinist’s level and trammel rods. You want less than 0.0005 in/ft variation – yes, it’s that tight.

- Treating Alignment as a “New Press” Task Only

Alignment isn’t a one-time install procedure. Wear happens. Components shift. Operators drop heavy tooling. It all adds up.

Fix it: Establish a routine re-alignment program. Combine daily visual checks with periodic full inspections using both traditional tools and laser measurement, if available. If you’re not checking alignment at least quarterly, you’re flying blind.

Final Thought

Press alignment isn’t glamorous, but it’s foundational. A perfectly built press will still produce subpar results if alignment is neglected. And a well-maintained older press can outperform newer machines when alignment is dialed in.

At Dunaway, we understand that alignment is both a maintenance issue and quality control imperative. If you’re chasing recurring surface issues, inconsistent extrusion or unusual component wear, alignment is the first place to look.

And when you need support – from on-site alignment services to replacement components – we’re ready to help you bring it back to center.