Don’t Skip These 8 Maintenance Tasks if You Want Your Press to Run Smoothly

At Dunaway, we’ve learned there’s a world of difference between hitting pause for routine maintenance and getting blindsided by unplanned downtime.

Most plants have the basics down – daily inspections, alignment checks, the usual suspects. But it’s those smaller maintenance tasks, the ones that slip through the cracks, that’ll bite you when you least expect it. They’re the difference between preventing premature wear and facing down a costly repair bill.

Here are 8 maintenance tasks that every extrusion plant should have on their radar, but too many don’t:

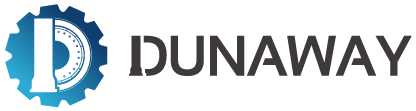

When you start seeing brass transfer building up on the guideways, that’s your press telling you something’s wrong. It’s usually poor lubrication or a misalignment issue brewing. Let it go, and you’re looking at accelerated wear and alignment headaches down the road. The fix? Regular inspections and staying on top of cleaning those guideways and guide shoes.

- Feel Those Cylinder Rods for Heat and Bypass Issues

Here’s a simple test that tells you a lot: if your crosshead or container cylinder rods are running hot to the touch when they’re under pressure, you’ve probably got hydraulic fluid bypassing the piston head. That’s seal failure talking, and it’s not going to get better on its own. Make it a habit to check during full-load conditions. It’ll save you from much bigger hydraulic problems later.

- Don’t Skip Checking Tie Rod Pre-Stress Under Load

Feeling for clearance between those tie rod nuts and platen flanges is not busy work. It matters. Even a tiny 0.001″ gap means you’ve lost pre-stress, and if those tie rods fail, your entire press structure is compromised. It’s worth the time to check them periodically under full tonnage. Your press’s long-term integrity depends on it.

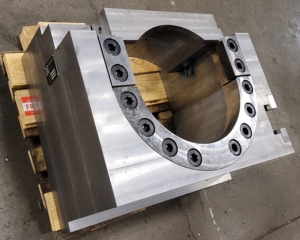

- Run a Straightedge Along That Front Platen Pressure Ring

Die alignment problems often start right here at the pressure ring. A straightedge and feeler gauge will show you distortion or “coining” that’s messing with your die stack uniformity. Catch it early and smooth it out or re-machine it before the misalignment spreads and causes bigger problems.

- Don’t Let Die Carrier Pocket Wear Slide

When tool holders/die saddles/die pockets start showing wear or get clogged up with aluminum buildup, your whole tooling change process takes a hit. These seemingly small issues throw off butt shearing accuracy and mess with alignment. Stay ahead of it. Inspect regularly, clean thoroughly and don’t hesitate to re-machine when needed.

- Keep Those Die Changer and Front Platen Contact Areas Smooth

See scoring where the die changer passes the platen? That’s not just cosmetic damage. All that friction leads to misalignment and unnecessary wear throughout your system. Grind those areas smooth and keep them lubricated. Your press will thank you with smoother operation and less stress on the components.

- Use Proper Fixtures or Jigs for Billet Loader Safety

Let’s be clear about this one: the billet loader area is one of the most dangerous spots for maintenance work. Never, and I mean never, rely on makeshift blocks or jury-rigged setups to block up the loader while working in the area. Invest in proper jigs, slings, or fixtures designed for safety, and always follow your lock-out/tag-out procedures. This isn’t just about preserving equipment. It’s about getting everyone home safe!

- Get Smart About Modern High-Temp Lubricants

The days of coating everything in graphite are long gone. Today’s precision lubricants (like boron nitride sprays and automatic dummy block sprayers) are engineered for specific applications and frequencies. Too little and you’re not getting the protection you paid for. Too much and you’re dealing with buildup issues. Work with experts who know these products to dial in the right approach for your operation.

Final Thought

Routine doesn’t mean optional. At Dunaway, we’ve seen too many plants learn this lesson the hard way. Whether you’re looking to tighten up your PM program or train your crew to spot problems before they become expensive surprises, we’re here to help you work smarter and stay productive.

Need help improving your PM program or upgrading critical components? Contact Dunaway or explore our Extrusion Press Services to learn more.